In March 2025, the roar of the first fully automated high-speed printing production line signaled the successful commissioning of our flagship project—the Smart Green Manufacturing Base—a benchmark initiative in the flexible packaging industry. Built with substantial investment, this base marks a leap forward in our capacity scale, technological innovation, and sustainable development capabilities, delivering more efficient and eco-friendly flexible packaging solutions to global clients in food, pharmaceutical, and daily chemical industries.

Intelligent Infrastructure Redefines Production Paradigm

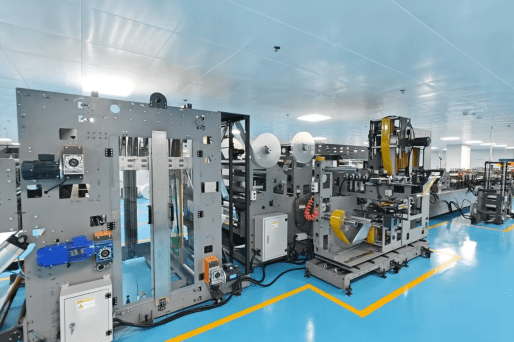

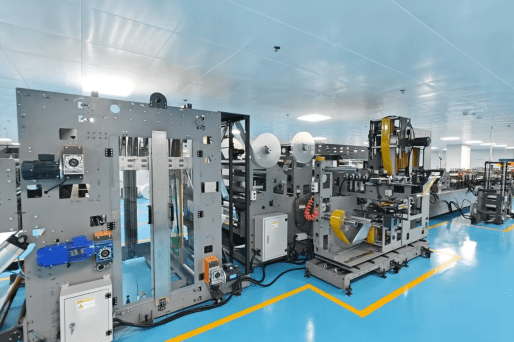

Spanning 30,000 square meters, the new base houses 14 fully automated production lines covering end-to-end processes including gravure printing, solventless lamination, high-speed slitting, and intelligent bag making. These lines integrate advanced automation technologies to ensure precision and efficiency across all manufacturing stages.

In quality management, a robust "prevention-detection-improvement" closed-loop system is implemented, providing end-to-end quality assurance from material R&D to finished product delivery. This comprehensive control framework ensures consistent excellence for high-end clients, whether in material selection, production execution, or final inspection.

Green Manufacturing Fulfills Industry Responsibility

As a pioneer in the flexible packaging industry's green transformation, the base adopts cutting-edge eco-friendly processes:

Energy Management: Equipped with a 10MW distributed photovoltaic power station, supplying 30% of the facility's annual electricity needs. A fully enclosed solvent recovery system in printing operations cuts VOCs emissions by 85% compared to traditional processes.

Circular Economy: A waste film recycling line featuring(crushing-pelletizing-modification) technology achieves 100% recycling of production waste, reducing annual solid waste discharge by 8,000 tons.

"Our transition from 'manufacturing' to'smart + green manufacturing' has reduced unit (energy consumption per unit output) by 40% compared to our old facility," stated the base planning director. "This isn't just a cost advantage—it's a direct response to global clients' urgent demand for sustainable packaging."

Hot News

Hot News